You are here: Home » Energy » Insight Hub » Case Studies

Case Studies

At Lucideon, we have worked on many different and diverse projects across a wide range of materials and industries. Read here about some of the work we have done.

Case Studies

-

Flash Sintering Helps to Clean up Green Energy

Fuel cell technology has a major role to play in the decarbonization of our infrastructures. Solid oxide fuel cells, which use a ceramic electrode and electrolyte layers, achieve higher efficiencies, longer lifetimes and fuel flexibility over other fuel cell technologies, offering advantages in many stationary power and transport applications.

-

Lucideon Provides Customized Materials Testing Project for INS (Phase 2)

In the second phase of this project Lucideon delivered a destructive testing programme of various bolt grades and sizes, loaded in double shear, single shear, dynamic single shear and tension.

-

Lucideon Provides Customized Materials Testing Project for INS (Phase 1)

Lucideon delivered a testing programme on the various steel types, providing robust mechanical property data through the delivery of tensile testing at temperatures ranging from minus 40°C to plus 600°C.

-

Lucideon Helps Energy Client with a Processing Issue

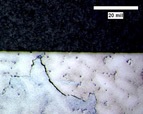

Defect analysis using optical microscopy, SEM imaging, EDS element mapping and EBSD

-

When the Unexpected Happens to Your Polymer Components

Failed polymer components analyzed at Lucideon

-

Brickwork Evaluation of Battersea Power Station

Brickwork testing for the Battersea Power Station redevelopment project

-

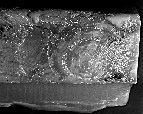

Lucideon Assists in Identifying Root Cause of Cracking in Additive Manufactured Components

Lucideon additive manufacturing expertise helps identify root cause of product failure.

-

Change of Supplier Leads to Polymer Product Failure

Lucideon identified root cause of failure following a change of supplier

-

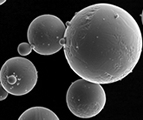

Lucideon Helps Additive Manufacturer Solve Powder Inconsistency

Lucideon expertise help develop powder conditioning procedure to improve processing.

-

Safe Confinement at Chernobyl Nuclear Power Plant

Testing of unique cladding system and its components

-

Removing Chromium by 2013 - Development of New Anti-Corrosion Coatings

Critical technology review carried out in partnership with Indestructible Paint Ltd.

-

Cleanliness Measurement on High Performance Metal Components

Application of Lucideon's cleaning validation procedure - Validata

-

Development & Sourcing of a New Glass Material for Mansol Preforms

Testing & material trials

-

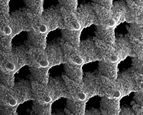

Surface Characterization of Gas Turbines

Lucideon assisted Goodrich Corporation with surface analysis of a chromium containing coating

-

Powders Expertise - Investment Casting Control

Lucideon's expertise sought regarding ceramic slurries for investment casting.