You are here: Home » Energy » Fuel Cells

Energy storage solutions are required in sizes ranging from personal use to commercial storage. All types of energy storage devices include multiple materials, and complex chemistries, surface and interface reactions, efficiency and cost-out challenges. Leverage Lucideon's materials expertise, characterization techniques and practical industry experience to rapidly advance your product designs and solve your most challenging materials issues.

Product and Process Development

- Powder composition & morphology

Identification of the critical stoichiometry, morphology and an investigation of impurities in your powders.

- Interface condition assessment, bonding & adhesion failures

Characterization of interfaces within the cell membranes, sealing interfaces and contact areas to understand the bonding between layers after processing, testing and thermal cycling.

- Degradation assessment

Understanding the condition of fuel cells after testing, identifying the critical parameters required to generate high power densities and the mitigation of degradation kinetics.

- Coating integrity assessment

Evaluating your coating's performance after deposition and testing to optimize application parameters and decrease product development times.

- Glass seal evaluations

Characterizing crystallization temperatures, composition and glass-to-metal interfaces for the development of fuel cell stacks.

- Failure analysis

Investigating the root cause of material degradation and failures, enabling you to increase the efficiency and extend the lifetime of fuel cell products.

- Contamination identification

Contaminant identification to look for impurities that could be indicative of failure modes or degradation within your system.

Technology Platforms

- Ceramics processing improvements

- Finite Element Sintering

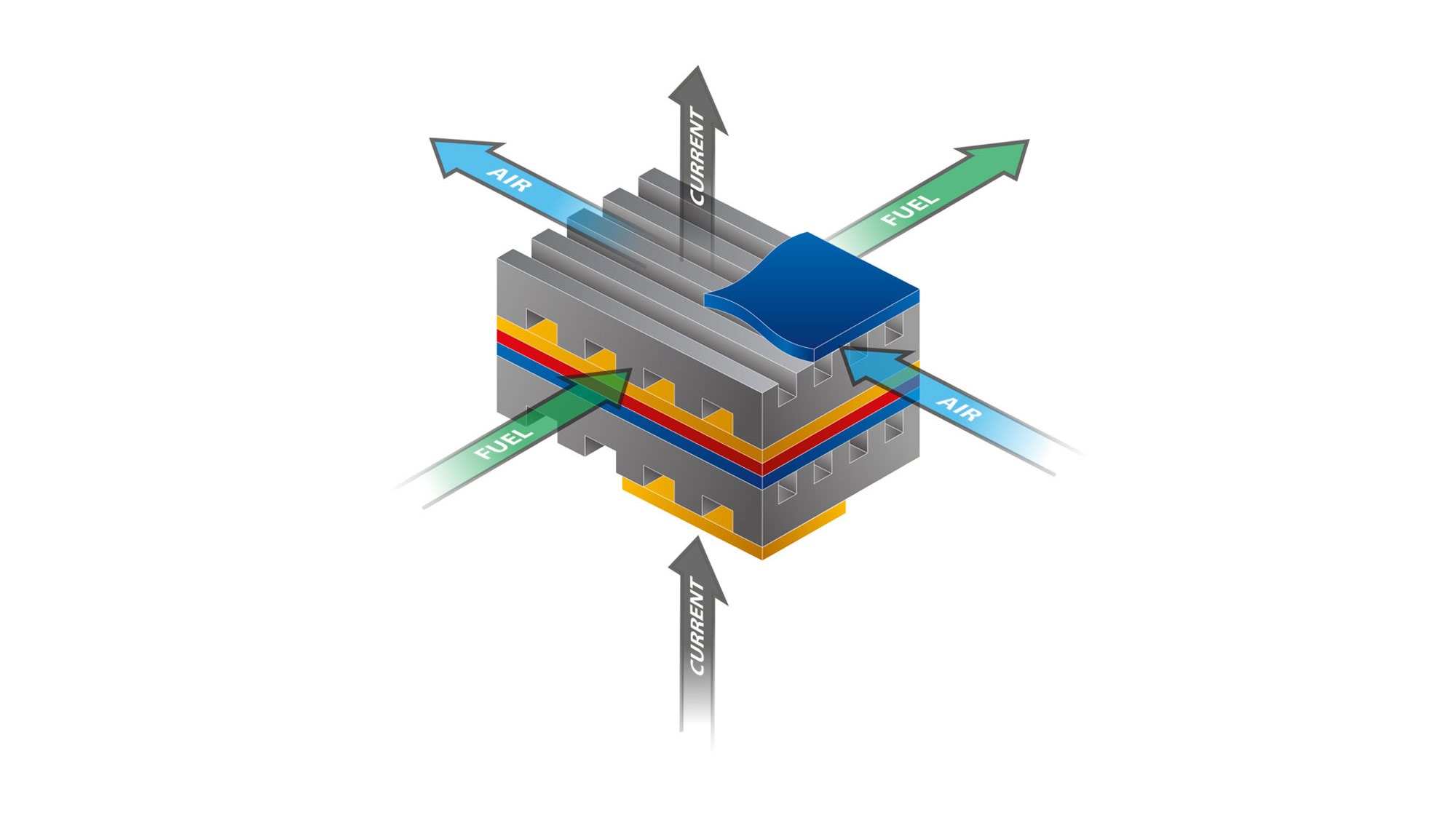

- Solid oxide fuel cells

Solid electrolyte batteries to lower costs and provide enhancement of materials properties.

- SOFC materials development

Shortening product development time to create a superior product by adjusting the critical parameters required to both generate high power densities and mitigate degradation kinetics quickly.

Testing

- Metallographic cross-section examinations

Metallographic preparation of ceramics, glasses and metals, and high-quality imaging and analysis techniques to provide a fundamental understanding of fuel cell material behavior.

- Density characterizations

Measurement of the density properties of components made with Powder Metallurgy, MIM and Additive Manufacturing.

- Elemental diffusion profiles

Characterization of elemental diffusion profiles at interfaces through techniques including EDS line scanning and mapping, EBSD, and various analytical chemistry techniques.

» Find out more about our accreditations here.