You are here: Home » Testing & Characterization » Surface Analysis » Tribology

Tribology

Tribology is the science and technology of interacting surfaces in relative motion. Design, friction, lubrication and wear of mating, moving surfaces are all inter-linked and product performance related.

Our surface science experts understand that it is not just the mechanical material properties and topography of a surface that play an important role in tribological performance, surface chemistry and change in chemistry under specified loading conditions can significantly affect the ability of a product to perform.

Case Study:

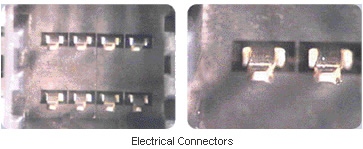

Electrical Contacts

Electrical contacts are readily found in critical applications in modern transportation. This includes aeroplanes, trains and automobiles.

We are increasingly relying on electronics for safety and comfort; airbags, ABS, critical control systems, air conditioning units etc. Some automotive and aviation applications incorporate several kilometres of cabling. At some points connections have to be made, either between cables or directly on printed circuit boards. The integrity of electrical connections is often critical.

Vibrations in connectors in this type of application cannot be avoided. These cause very small relative movements of the two mating parts (male and female) of a connector.

Because of these relative displacements, typically tens or hundredths of millimetres (micrometers), wear occurs on the surfaces. This wear may produce small wear particles, such as oxides, forming an interface which will increase electrical resistivity, leading to an electrical failure i.e. a 'bad' contact. This is a very real problem. It has been estimated that more than 50% of all car problems that are attended by automobile clubs relate to bad electrical contacts.

To be functional, connectors typically must have some contradictory requirements. They must slide to make the installation and connection easy. However, they should not slide too much to avoid wear and destruction of the mating surfaces.

The classic connector has a very soft top layer (Sn or Au) that is smeared out by the installation, forming the best possible electrical contact. Vibrations, after long periods of time, result in this coating wearing away. For investigating this, the combination of sliding wear/vibration tests and surface analysis gives a vital indication of performance prior to products being released in the field.

The effects of materials choices can be evaluated rapidly eliminating expensive vehicle trials or 'in-field' reliability issues.

Case Study:

Lubricant Additive Packages / Pin-on-Disc Testing

Friction coefficients between mating surfaces can be readily measured by one of a series of tribological tests. One such test is pin-on-disc.

Two test systems are available, a standard test and light load test. The standard test is used for loads associated with applications such as metal to metal contacts and oil lubrication systems, whilst light load test equipment is utilised in medical device, electronic and fibre optic applications, for example.

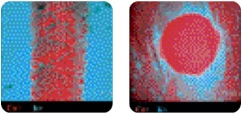

The DSIMS images below show the overlays of calcium and potassium from a lubricant additive.

The images are from the wear scar and ball used in a pin-on-disc test.