You are here: Home » Materials & Process Consultancy » Additive Manufacturing » Additive Manufacturing Materials Testing

Additive Manufacturing Materials Testing

- How do I validate that my AM component meets the design intent?

- Does my process demonstrate consistent quality?

- How do I qualify my materials / products vendor?

Our diverse background in materials development and processing allows us to troubleshoot the unforeseen challenges inherent with the adoption of new technologies. Whether you are establishing new design criteria for your additive manufactured component, validating against an established design specification or troubleshooting a non-conforming component, we assist in overcoming your challenges, supporting your supply chain, and accelerating the development cycle through additive manufacturing component testing and validation.

Additive Manufacturing Quality Control and Assurance

As an unbiased third party, our experts will regularly qualify vendors by evaluating products in reference to a specification. Additionally, we perform "first piece" and "pilot lot" qualifications or perform routine additive manufacturing testing to support your quality programs.

Development and Evaluation of Testing Programs and Specifications

We can develop customized programs to validate the quality of your additive manufactured component and ensure that it's fit for purpose. Many of our clients utilize our expertise to allow interpretation and development of specifications.

Additive Manufacturing Testing

With a wide range of additive manufacturing testing capabilities, Lucideon's experts go beyond the numbers to provide advantage through insightful analysis.

- Chemical Analysis - It is critical that manufacturers understand chemical properties of the powders and products in the additive manufacturing process. Discover more...

- Quantitative chemical analysis

- Carbon sulfur analysis

- Electron microprobe

- FTIR

- ICP-MS

- Thermal analysis

- Chemical homogeneity

- DTA determination of phase transition temperature.

- Mechanical Testing - With both customized and standardized testing, we perform mechanical tests under extreme environmental conditions, ranging from highly elevated to sub-ambient temperatures. Discover more...

- ASTM test methods

- Tensile strength, hardness, fatigue

- Model comparison / validation

- 3D Strain analysis

- Creep / stress relaxation.

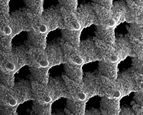

- Metallurgical Analysis - In order to understanding the effects of build direction, process variables and design, our skilled metallurgists utilize techniques ranging from optical microscopy and SEM-EDS analysis to electron microprobe and advanced surface analysis techniques. Discover more...

- ASTM test methods

- Microstructural characterization

- Post-processing assessment

- Porosity evaluation

- Characterization on interface layer

- Particle Shedding Analysis.

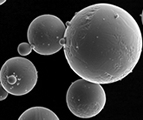

- Powders Evaluation - Our experts understand that product quality and operational efficiencies are highly dependent on the characteristics of additive manufacturing powders.

- Particle Size Distribution

- Morphology

- Flow

- Quantitative shape analysis

- Powder Imaging

- Density.

- NDT - Lucideon supports your additive manufacturing QC and development efforts with specialized NDT techniques - multiple ways to compare your builds to the model and visualize defect characteristics.

- Computed Tomography

- White Light Interferometry

- Surface Profilometry

- Dimensional Validation.

- Performance Evaluation - Validate the quality of your additive manufactured products and ensure that they're fit for purpose.

- Cleaning Validation

- Fatigue

- DIC

- Corrosion

- Atomic Force Microscopy

- Oxidation (Burner) Testing.