You are here: Home » Insight hub » Case Studies » Lucideon Assists in Identifying Root Cause of Cracking in Additive Manufactured Components

Lucideon Assists in Identifying Root Cause of Cracking in Additive Manufactured Components

Additive manufacturing provides a new challenge not previously seen through subtractive machining - the ability of the end user to dictate the material structure of a component being produced. With this new capability comes unique failure mechanisms, processing challenges and new structure-process-property relationships. Understanding all of these is the key to identifying the root cause of Client problems and offering a comprehensive solution.

The Challenge

One of our Clients was experiencing periodic cracking in components that were being printed at their facility, however they were unable to correlate the root cause to any of their processing parameters.

What We Delivered

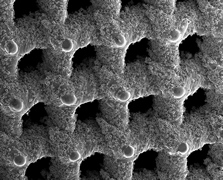

Leveraging the experience of our Additive Manufacturing (AM) team, our dedicated testing and analysis laboratories and background in powder and microstructural characterization - we were able to analyze both the residual stress inside the component and the changes in the recycled powder, both of which were considered likely contributors to the failure. We were able to identify the root cause as an issue in the quality of the recycled powder, and were able to recommend changes to powder handling processes, recycling programs and the in-line process settings, in order to prevent these issues moving forward.

Value to the Client

Our Client was able to confidently produce high quality additive components without the scrap costs associated with periodic failures, or the concern of reliability issues in their end use application, reducing the overall liability for the company.