You are here: Home » Testing & Characterization » Test methods » Evaluation of Porous Coatings on Medical Devices - ASTM F1854 - Test Method

Evaluation of Porous Coatings on Medical Devices - ASTM F1854 - Test Method

Lucideon provides a thorough evaluation of all the parameters associated with the analysis of porous coated medical devices and implants per the ASTM F1854 standard.

Overview

The F1854 standard has long been in practice and used for the analysis of conventionally coated medical implants and devices. Sintered beads and wire and plasma spray porous coatings have commonly been evaluated using this standard test method. Lucideon has developed the metallurgical techniques to perform the proper sampling, sectioning and polishing to effectively image porous coatings in cross-section and apply the various test methods described in this standard. The recent evolution of additive manufacturing (AM) and 3D printing technologies such as electron beam manufacturing (EBM), Direct Metal Laser Sintering (DMLS), Selective Laser Melting (SLM), and others which employ powder bed fusion have created unique and complex porous surfaces. Lucideon has adapted the F1854 analysis to these more complex coating structures as well.

Expertise and Test Methodology

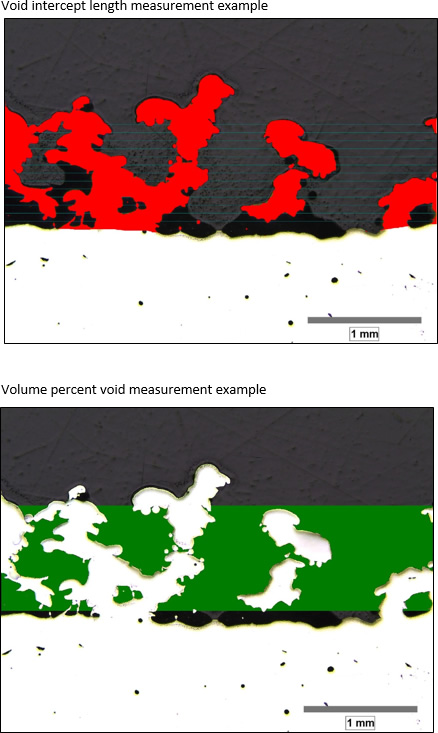

The test methodology involved here begins with proper sectioning, mounting and polishing. Lucideon has developed methods and procedures to take sections which effectively represent the true nature of the porous coating. Once properly polished, optical measurements and image analyses are applied to the cross-sections of the test sample to provide the measurements required by the standard. Again, metallographic procedures and image analysis programs have been expanded to include the complexities associated with porous coatings made by additive layer manufacturing (ALM) methods. Measurements for mean coating thickness, volume percent void and mean intercept length are provided along with the required statistical analysis. If requested, surface microstructural analyses can also be performed to document the presence of anomalies such as alpha case and other microstructural defects. Additionally, as Lucideon and its team of metallurgists have gained extensive experience with all the AM methods, consultations can also be provided on any metallurgical issues that might arise as a result of this analysis.

Form of Results

Reports are provided with the specific measurements required by the standard. Associated images representing the applied image analyses methods, as shown below for AM material, are also provided. Assessments of consistency and uniformity can also be provided upon request.

Related Tests

- Preparation of Metallographic Specimens – ASTM E3

- Guide for Reflected-Light Photomicrography– ASTM E883.