You are here: Home » Materials Technologies » MIDAR® Technology

MIDAR® Technology

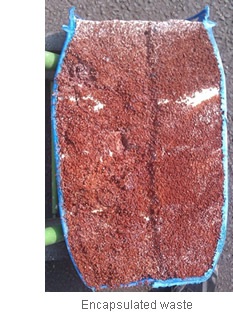

MIDAR® geopolymer technology is both revolutionary and sustainable, with numerous applications from encapsulating waste (including nuclear) to acting as an alternative production method for construction products and ceramics.

What is MIDAR® Technology?

The MIDAR® technology platform uses a low temperature chemical reaction to consolidate a refractory material and form a robust body with high strength and chemical stability. The resulting material can be used as an encapsulation and immobilization agent by incorporating a solid or liquid waste stream into the inorganic solid matrix that is formed during the reaction. The MIDAR® geopolymerization process can be varied to accommodate different methods of forming: extrusion, moulding and casting.

The technology can also be used to make solid or aerated building products.

Why use MIDAR® Technology?

- Potential to utilise waste raw materials to form a high strength, solid matrix similar to ceramics

- As the technology is based on a chemical reaction, no firing is required - this reduces energy usage and carbon emissions

- The resulting material is fire, frost, chemical, shock, water and heat resistant

- It has a low level of leachability of encapsulated materials (e.g. radioactive substances)

- Curing time can be altered to suit system needs

- The resulting solid has negligible shrinkage (near net shape)

- It is a technology that has been honed by an experienced team of scientists and engineers whose aim is to produce materials technologies that address your technical challenges and commercial needs.

MIDAR® Geopolymer Compared to Cement and Organic Polymers in an Encapsulation / Immobilization Application:

| Attribute | Cement | Organic or Silicone Polymer | MIDAR® Geopolymer |

|---|---|---|---|

| Solids loading | Low | Low | High (up to 50%) |

| Resistance to fire and frost | Low | None/ Limited | Good |

| Chemical resistance | Limited | Limited | Good |

| Shrinkage on curing | Low | Low to high (polymer dependent) | Negligible |

| Application method | Pumped (high viscosity) | Pumped (high viscosity) | Poured or pumped |

New BSI Standard for Alkali-activated Cementitious Material

In March 2016, a new BSI standard (PAS 8820) was published to define raw material and product performance specifications to give manufacturers of construction materials the opportunity to develop products based on alkali activated cement technologies, safe in the knowledge that they comply with a European standard of approval. The standard refers to, and benchmarks against, a number of well used cement standards, ensuring consumer confidence in the new technology.

Prior to the publication of the standard, planning a route to the European market for alkali based cementitious construction products proved difficult; though technically proven to meet the requirements for many applications, there was a lack of acceptance by building standards.