You are here: Home » Healthcare » Insight Hub » Case Studies

Case Studies

At Lucideon, we have worked on many different and diverse projects across a wide range of materials and industries. Read here about some of the work we have done.

Case Studies

-

Lucideon Solves Processing Challenge

One of our clients was experiencing issues with fragility of their tableted products. This caused tablets to break up on the conveyor belts prior to packaging, leading to excess wastage. We immediately set about understanding their individual situation in more detail. The issues were intermittent and there were numerous variables in the process that could have been contributing to this issue.

-

Lucideon Method Development Helps Nobel Biocare in Medical Device Optimization

Lucideon was approached by Nobel Biocare to characterize the surface chemical composition of medical implants to quantify the surface concentration of hydroxyl groups on the surface.

-

Lucideon & GSK Consumer Healthcare Compare the Effects of Different Toothpastes on Teeth

GSK Consumer Healthcare wanted to compare the effect of two stannous fluoride containing toothpaste formulations (GSK’s Sensodyne Sensitivity and Gum and another marketed product) in terms of dentine tissue loss.

-

Lucideon Validates the Efficacy of Sterilizing Products

Using our internal knowledge, and guided by the various FDA guidance documents on cleanliness and disinfection, we developed a testing and validation strategy, along with the corresponding protocols

-

Surface Cleanliness of Orthopaedic Instruments

Lucideon assists in identification and prevention of staining of orthopaedic instruments

-

When the Unexpected Happens to Your Polymer Components

Failed polymer components analyzed at Lucideon

-

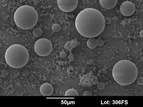

Croda & Lucideon Further Optimize Coating Coverage and Application

Lucideon testing helps to optimize the coating process of powders

-

Surface Cleanliness of Dental Instruments

Lucideon’s expertise in analytical sciences helps identify cause of surface contamination in client’s product

-

Encapsulation of Bleach

Encapsulation of bleach helps to maintain activity in application environment

-

Lucideon Helps Consumer Product Manufacturer Measure Effectiveness of Washing Machine Soap

Lucideon method development helps quantify effectiveness of washing machine soap

-

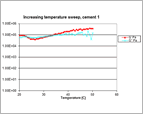

Lucideon Helps Identify Root Cause of Syneresis in Bone Cement and Implement New QC Protocol

Lucideon experts help identify the cause and solution to bone cement syneresis

-

Lucideon Helps Control Bone Cement Homogeneity

Lucideon's experts help to control the homogeneity of bone cement

-

Lucideon Performs Method Development to Prove Efficacy of Dental Adhesives

Method Development to Test the Effects of Using Dental Adhesives

-

Change of Supplier Leads to Polymer Product Failure

Lucideon identified root cause of failure following a change of supplier

-

Spontaneous Failure of a Medical Device During Secondary Processing

Polymer expertise helps with product failure issues

-

Fracture of a Dyed Medical Instrument

Analytical services for a medical device manufacturer

-

Lucideon Helps Determine Impact of Hot Isostatic Pressing on Fatigue Life of Ti-6Al-4V Component

Lucideon expertise helped a client with additive manufactured implants.

-

Lucideon Helps Consumer Healthcare Manufacturer Understand Stability Inconsistency - Part 1

Lucideon helps consumer healthcare manufacturer with stability inconsistency.

-

Lucideon Helps Consumer Healthcare Manufacturer Understand Stability Inconsistency – Part 2

Lucideon helps consumer healthcare manufacturer with stability inconsistency using FED analysis.

-

Lucideon Expertise Helps with Additive Manufacturing HIP Issues

We helped our client with discoloration issues after HIP.

-

Lucideon Helps Dental Crown Manufacturer Fix Processing Problems

Lucideon expertise helps crown manufacturer improve quality

-

Lucideon Helps Toothpaste Manufacturer to Prove Efficacy of their Product for Tubule Occlusion

Lucideon testing helps to prove effects on tubule occlusion

-

Lucideon Helps Oral Care Manufacturer to Compare Fluoride Penetration of own Product with Competitor

Lucideon helps in product performance comparison

-

Novel Processing of Bioactive Inorganic Materials

Lucideon expertise allows new elements to be included in products

-

Optimization of Tablet Manufacture

Optimization of powders for tablet pressing

-

Lucideon Helps Greatbatch Medical to Gain FDA Acceptance

Lucideon has worked with Greatbatch Medical to help them gain FDA approval.

-

Lucideon Investigates Hair Care Products

Lucideon uses surface analysis to investigate hair care products

-

Topographical Surface Analysis Helps Skin Care Product Claims

Topographical analysis of skin

-

Surface Yellowing of a Drug Tablet upon Light Exposure

ToF-SIMS investigation into tablet discolouration

-

Crystallite Contamination in a Drug Formulation

Analysis by time-of-flight secondary ion mass spectrometry