You are here: Home » Healthcare » Vascular » Drug Release Profiles

Drug Release Profiles

The next generation of vascular care materials will offer greater drug-eluting and repair-promoting properties. We have the technologies to control the release of key actives, making delivery more efficient.

Bioresorbable Stent Materials

A challenge in developing stents is that the materials which make up the stent remain in the body forever, even when they have successfully done their job. To make a stent bioresorbable, a balance between retention of mechanical properties and degradation rates of the materials is vital.

Lucideon has developed a series of inorganic and polymeric materials, and optimized polymer/composite processing techniques, in order to achieve:

- Design of the correct formulation in terms of solubility of the inorganic materials and loading level to control the degradation rate of the composite

- Incorporation of drugs into the formulation with sustained release properties but without compromising the mechanical performance.

We manipulate materials via novel manufacturing processes and compositions to deliver the chemical and physical properties that your product needs. These can be applied as coatings or bulk materials depending on the application.

We have developed an inorganic system (iCRT - Inorganic Controlled Release Technology) for encapsulation and/or delivery of actives, including inorganic and organic compounds and ions.

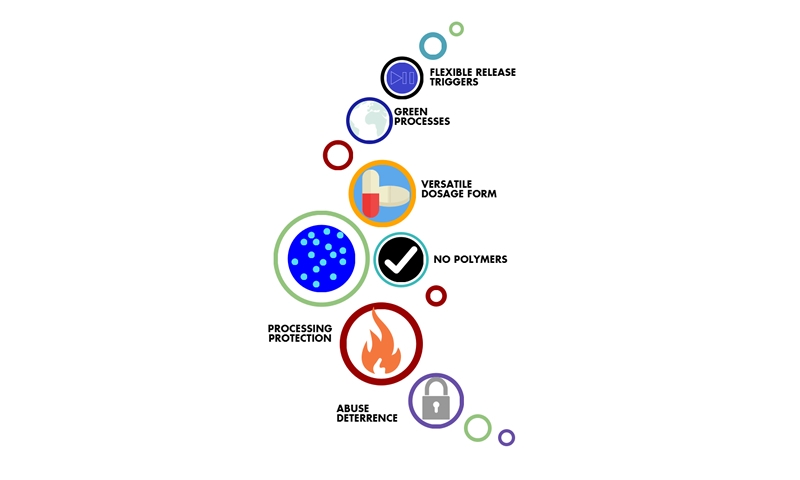

Some Fundamental Benefits of the Technology:

How the Technology Works

- iCRT allows the active ingredient to be encapsulated into an inorganic amorphous matrix

- Release of the active can be via diffusion from a porous insoluble matrix, or via dissolution of a soluble carrier matrix and consequent release of actives

- The release can be triggered or delayed by changes in the environment e.g. pH, temperature, aqueous media, ionic concentrations, etc.

Control & Protect Functional Ingredients

Our smart technology helps you improve the longevity or durability of your product's effectiveness by controlling the exposure of your functional ingredient to the environment.

Optimizing & Adding Features

As well as using this platform to encapsulate materials, we can exploit the manufacturing processes to improve your materials properties, such as:

- Add or improve optical features e.g. color, transparency

- Trransform physical properties, e.g. porosity, physical state

- Change reactivity, e.g. solubility, stability in different environments/solvents.