You are here: Home » Healthcare » Orthopaedic Implants » Additive Manufacturing Support

Additive Manufacturing Support

Whether you produce additively manufactured (AM) components and devices or you are just starting on your journey with additive manufacturing, we provide a full cycle testing and consultancy service to help you get the most from your processes and products.

Cleaning Validation and Method Development

In healthcare, and with implants in particular, additive manufacturing can pose a big problem with cleanliness because of the porosity of AM products. Porous structures have the potential to harbor stray particles which can, overtime, migrate out of the implanted product and into patients. We provide manufacturing process and reprocessing cleaning validation services to help ensure your devices are safe for use, as well as method development for your more complex and unique challenges.

Mechanical Strength and Failure Analysis

Many AM products suffer failure mechanisms under lower strains than non-AM devices. Our materials scientists and engineers are failure analysis experts, with industry experience working with virtually every material that could be used. We are industry leaders when it comes to working with metals, polymers and ceramics, and our analytical capabilities can help to identify any potential mechanical faults with your products. Our expert team then utilize their knowledge to consult on the best solution to improve your product and its properties.

We help you from the outset of your project, by characterizing and optimizing your starting powder material, and then work alongside you during product design to really understand the impact of the new process.

As materials experts, we care about what is going on at the microstructural level, as well as the component level. Some of the projects we have worked on include:

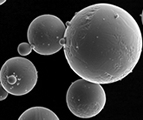

- Starting powder characteristics (size, flow, composition) and the impact on the AM process

- Cleanliness of AM parts and how to design a cleaning protocol that is effective and satisfies the regulatory bodies

- Which quality control measures are really important for AM products vs. traditional processing routes

- Investigating how the AM microstructure affects your products, how much it influences its mechanical properties and fatigue strength, and how can it be improved

- Analyzing residual debris within your porous structure – how detrimental it is and how to remove it.