You are here: Home » Insight hub » Case Studies » Flash Sintering Helps to Clean up Green Energy

Flash Sintering Helps to Clean up Green Energy

Context

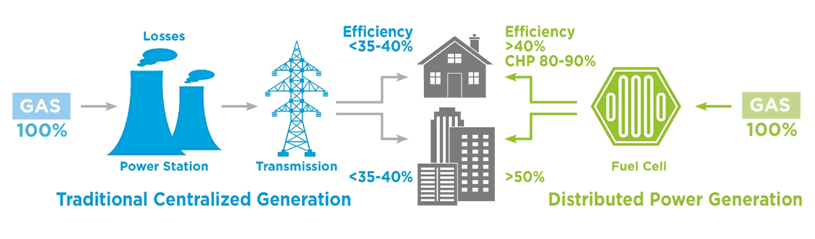

Fuel cell technology has a major role to play in the decarbonization of our infrastructures. Solid oxide fuel cells (SOFC), which use a ceramic electrode and electrolyte layers, achieve higher efficiencies, longer lifetimes and fuel flexibility over other fuel cell technologies, offering advantages in many stationary power and transport applications.

Challenge:

Widespread adoption of fuel cell technology in applications such as residential power will only follow once the cost of the systems is low enough to be offset by lifetime savings on energy.

What we do:

Initial results indicate that Lucideon's Flash Sintering technology achieves microstructures and performance comparable to conventional results. Designs for scale up are underway, in parallel to further process development, to demonstrate the improved production rates possible.

Benefit:

Clean energy generation is only as green as the methods used to produce the systems. Due to the lower sintering temperatures and times, Flash Sintering promotes a decrease in energy consumption and increase in productivity, resulting in a lower cost base per unit and thus allowing wider adoption of green technology benefiting from this.