You are here: Home » Aerospace and Defense » Engines » Aircraft Engines

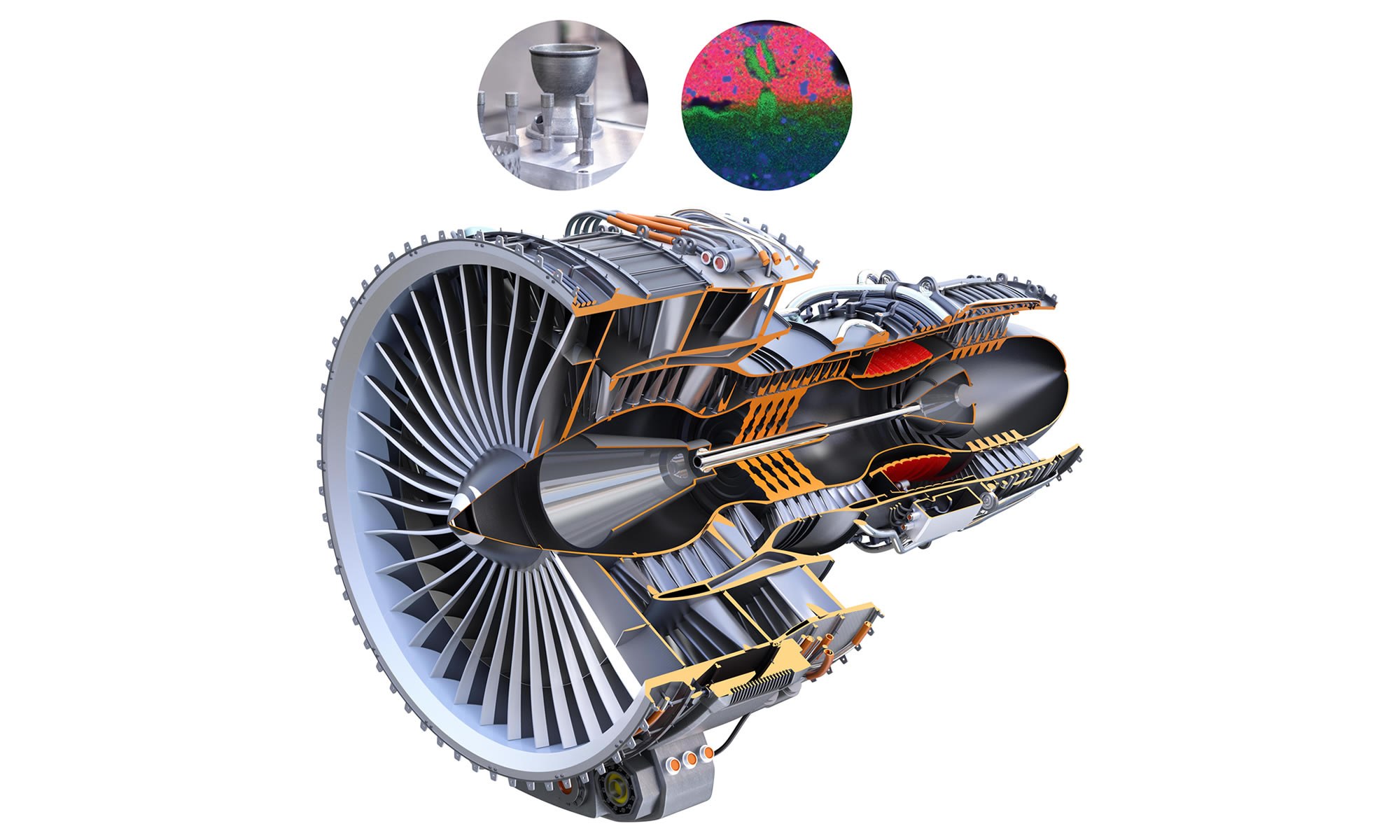

From nose cones and exhaust nozzles, to everything in between, we have a vast understanding of the materials and processes utilized in engines. As a materials partner, we can accelerate the development of your products by working with you during every stage of the product life cycle. Using our experience and knowledge in specialized testing, analysis and consultancy, we can also support the optimization of material systems and components. Partnering with Lucideon will enable you to gain a complete understanding of the properties and behaviors of your materials and the impact they have.

Additive Manufacturing Support (Metals & Ceramics)

Additive manufacturing (AM) offers a wide range of benefits and opportunities for the aerospace sector, but is not without its challenges. At Lucideon, we help you navigate the obstacles of component testing and validation, materials and process development, failure analysis and third-party benchmarking, to develop an AM product that is fit for purpose.

Thermomechanical Fatigue Testing

Understanding how materials will perform in service is essential for gas turbine design. Thermomechanical fatigue (TMF) testing simulates service conditions by simultaneously performing cyclic mechanical and thermal loading to accurately evaluate the combined effect on the materials fatigue life. The thermal and mechanical loads can be applied in or out-of-phase from one another. Our team of experts can work with you to develop a program that meets your specific requirements.

Physical Simulation of Materials Using Gleeble

The development of new high temperature and high strength alloys is at the core of enabling efficiencies in the aviation industry. These material advances are facilitated through the use of thermal-mechanical simulations, such as Gleeble, which allow the characterization of properties such as hot ductility, flow stress and weldability. Lucideon is the only ISO 17025 compliant laboratory in North America to offer Gleeble testing on a toll basis.

Microchemical Analysis of Barrier Coatings

Lucideon utilizes a state-of-the-art electron microprobe system with wavelength dispersive spectroscopy (WDS) in order to provide spot scans, depth profiling, and elemental mapping of advanced superalloys and their coatings, at a level unavailable using even the most advanced energy dispersive x-ray spectroscopy (EDS).

Hot Corrosion & Oxidation Evaluation

For conditions that begin at the surface, it is especially important to understand coatings and alloys, their composition, key properties and how they interact with other materials in their environment. Using our world-leading advanced surface science center and analysis equipment, such as x-ray photoelectron spectroscopy (XPS) and dynamic secondary ion mass spectrometry (DSIMS), the team of materials experts at Lucideon can obtain elemental, compositional and structural information of any coating. Chemical mapping and depth profiling are also available to characterize and understand coatings.

Custom Thermal Cycling & Shock Testing

We are able to determine the thermal and thermo-mechanical properties of high temperature ceramic coatings and their underlying superalloys. The techniques include thermal shock testing, thermal conductivity, specific heat and thermal expansion up to 1,600°C.

Custom Mechanical Testing

To ensure your aerospace components perform as intended over their lifetime, our experts can carry out a range of extensive physical and mechanical testing. This also ensures that materials and designs produce safe and robust components and products. We conform to a range of ASTM and ISO standards, but specialize in the development and execution of custom test programs – designed to help you understand how your products will operate in real-life operating conditions.

Ceramics and Composites Consulting

As operating temperatures of aircraft engines continue to increase, so do the high temperature requirements of the hot section materials. Ceramics play a key role in these advancements. The performance of ceramics and ceramic matrix composites (CMC) are dependent on the consistency and quality of the materials being produced. Lucideon’s expertise in powder characterization, rheology, sintering and failure analysis can all be leveraged in order to accelerate development of these key enabling technologies.